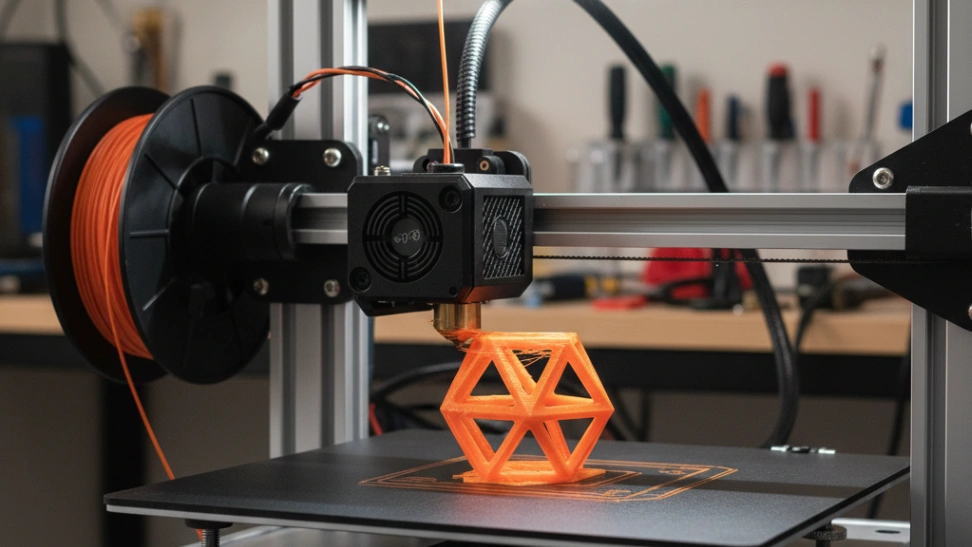

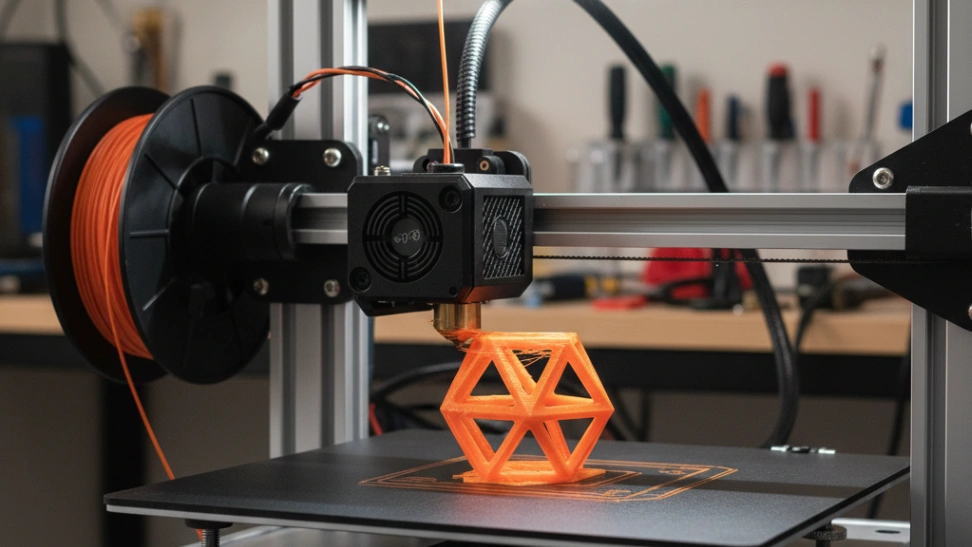

Create physical objects from digital designs using additive manufacturing.

3D printing transforms digital blueprints into tangible reality, offering unparalleled customization and rapid prototyping. It's a blend of digital design, material science, and mechanical engineering, accessible to hobbyists, designers, and engineers alike. From intricate miniatures and functional parts to bespoke artistic creations, the possibilities are limited only by imagination and material constraints. This technology democratizes manufacturing, allowing for on-demand production and iterative design processes that were once the exclusive domain of industrial facilities. Getting started involves understanding design software, printer operation, and material properties, but the reward is the ability to bring almost any idea into physical existence.

For the tinkerer who enjoys digital design and bringing imaginative concepts into tangible form.

Your journey starts here. Follow these steps to get started with 3D Printing.

Start with an affordable FDM (Fused Deposition Modeling) printer. The Creality Ender 3 V2 or Elegoo Neptune 3 are excellent entry-level options. Read reviews and compare features like build volume, print quality, and ease of use. A good starting point for research is the comprehensive guide on All3DP: https://all3dp.com/1/best-3d-printer-buyers-guide/

Every 3D print needs to be 'sliced' into layers for the printer to read. Download free slicer software like Ultimaker Cura or PrusaSlicer. Familiarize yourself with settings like layer height, infill density, and support structures. These programs translate your 3D models into G-code, the language your printer understands.

Many printers come with pre-loaded test models, or you can find thousands of free models on sites like Thingiverse or Printables. A simple calibration cube or a small decorative item is a good first print. Ensure your bed is level and the filament is loaded correctly before starting.

The first layer is critical for a successful print. Spend time learning to achieve a perfect, even first layer. Most printers have an auto-leveling feature, but manual adjustments are often still necessary. Watch tutorials specific to your printer model.

Our top picks for core tools to get you started.

Recommended items to enhance your experience.

As an Amazon Associate, HobbyStack may earn from qualifying purchases. Prices are estimates.

Skipping or rushing calibration steps like bed leveling, temperature towers, and retraction tests will lead to poor print quality, adhesion issues, and failed prints.

Cheap, unbranded filament can cause clogs, inconsistent extrusion, and brittle prints. Investing in reputable brands like Hatchbox, Overture, or eSUN is crucial for reliable results.

While defaults are a starting point, they rarely produce optimal results for every model or material. Understanding and tweaking settings like print speed, cooling, and supports is key to improving quality.

A hobby's core characteristics, based on community votes.

25% Solo

You tend to prefer your own company but are open to occasional, low-pressure social activities.

10% Energetic

You appreciate a balance of calm focus and moments of light, engaging activity.

45% Indoors

You are a homebody at heart, finding the most comfort and inspiration within your own space.

35% Creative

Your mind is a canvas, and you thrive on hobbies that offer total creative freedom and boundless self-expression.

20% Mental

You tend to prefer intellectual challenges but enjoy hobbies with some light physical activity.

Based on 24 total trait votes.

If you like 3D Printing, you might also enjoy these related hobbies.

Dive deeper with these community-recommended websites, guides, and forums.

A comprehensive resource for 3D printing news, reviews, guides, and tutorials.

A large and active community forum for asking questions, sharing prints, and troubleshooting.

Visual guides and tutorials from channels like Thomas Sanladerer, Maker's Muse, and Teaching Tech are invaluable.

Fused Deposition Modeling; a 3D printing process that builds objects layer by layer by extruding melted thermoplastic filament.

Software that converts a 3D model (STL, OBJ) into G-code instructions for a 3D printer.

The plastic material, typically on a spool, used in FDM 3D printers.

Standard Tessellation Language; a common file format for 3D models used in 3D printing.

The programming language that tells a 3D printer how to move and when to extrude filament.

This hobby's profile is shaped by the community. See what's most popular and cast your own vote to refine its identity.

The community strongly defines 3D Printing by aspects of the Technology & Engineering category.

Many users also associate 3D Printing with Crafts & Making.

A number of users see a connection between this hobby and Visual Arts & Design.

A number of users see a connection between this hobby and Science & Exploration.

Create physical objects from digital designs using additive manufacturing.

3D printing transforms digital blueprints into tangible reality, offering unparalleled customization and rapid prototyping. It's a blend of digital design, material science, and mechanical engineering, accessible to hobbyists, designers, and engineers alike. From intricate miniatures and functional parts to bespoke artistic creations, the possibilities are limited only by imagination and material constraints. This technology democratizes manufacturing, allowing for on-demand production and iterative design processes that were once the exclusive domain of industrial facilities. Getting started involves understanding design software, printer operation, and material properties, but the reward is the ability to bring almost any idea into physical existence.

For the tinkerer who enjoys digital design and bringing imaginative concepts into tangible form.

Your journey starts here. Follow these steps to get started with 3D Printing.

Start with an affordable FDM (Fused Deposition Modeling) printer. The Creality Ender 3 V2 or Elegoo Neptune 3 are excellent entry-level options. Read reviews and compare features like build volume, print quality, and ease of use. A good starting point for research is the comprehensive guide on All3DP: https://all3dp.com/1/best-3d-printer-buyers-guide/

Every 3D print needs to be 'sliced' into layers for the printer to read. Download free slicer software like Ultimaker Cura or PrusaSlicer. Familiarize yourself with settings like layer height, infill density, and support structures. These programs translate your 3D models into G-code, the language your printer understands.

Many printers come with pre-loaded test models, or you can find thousands of free models on sites like Thingiverse or Printables. A simple calibration cube or a small decorative item is a good first print. Ensure your bed is level and the filament is loaded correctly before starting.

The first layer is critical for a successful print. Spend time learning to achieve a perfect, even first layer. Most printers have an auto-leveling feature, but manual adjustments are often still necessary. Watch tutorials specific to your printer model.

Our top picks for core tools to get you started.

Recommended items to enhance your experience.

As an Amazon Associate, HobbyStack may earn from qualifying purchases. Prices are estimates.

Skipping or rushing calibration steps like bed leveling, temperature towers, and retraction tests will lead to poor print quality, adhesion issues, and failed prints.

Cheap, unbranded filament can cause clogs, inconsistent extrusion, and brittle prints. Investing in reputable brands like Hatchbox, Overture, or eSUN is crucial for reliable results.

While defaults are a starting point, they rarely produce optimal results for every model or material. Understanding and tweaking settings like print speed, cooling, and supports is key to improving quality.

A hobby's core characteristics, based on community votes.

25% Solo

You tend to prefer your own company but are open to occasional, low-pressure social activities.

10% Energetic

You appreciate a balance of calm focus and moments of light, engaging activity.

45% Indoors

You are a homebody at heart, finding the most comfort and inspiration within your own space.

35% Creative

Your mind is a canvas, and you thrive on hobbies that offer total creative freedom and boundless self-expression.

20% Mental

You tend to prefer intellectual challenges but enjoy hobbies with some light physical activity.

Based on 24 total trait votes.

If you like 3D Printing, you might also enjoy these related hobbies.

Dive deeper with these community-recommended websites, guides, and forums.

A comprehensive resource for 3D printing news, reviews, guides, and tutorials.

A large and active community forum for asking questions, sharing prints, and troubleshooting.

Visual guides and tutorials from channels like Thomas Sanladerer, Maker's Muse, and Teaching Tech are invaluable.

Fused Deposition Modeling; a 3D printing process that builds objects layer by layer by extruding melted thermoplastic filament.

Software that converts a 3D model (STL, OBJ) into G-code instructions for a 3D printer.

The plastic material, typically on a spool, used in FDM 3D printers.

Standard Tessellation Language; a common file format for 3D models used in 3D printing.

The programming language that tells a 3D printer how to move and when to extrude filament.

This hobby's profile is shaped by the community. See what's most popular and cast your own vote to refine its identity.

The community strongly defines 3D Printing by aspects of the Technology & Engineering category.

Many users also associate 3D Printing with Crafts & Making.

A number of users see a connection between this hobby and Visual Arts & Design.

A number of users see a connection between this hobby and Science & Exploration.